Rebar detailing software

Graphico PRO

Graphico PRO Program

A single software for different working systems

Graphico Pro is the main program for the production management of the Schnell Software products suite. It’s a rebar detailing software that allows, with its powerful and flexible graphical interface, both the performance of pieces by positioning including the reinforcement and the inclusion of commercial products in each order.

Graphico Pro stores all the project’s data, it manages the project phases and the orders for the production. Besides, All the data included in the program can be printed through customized reports divided into different areas such as customer management, order management, order management by location, element or for other commercial products.

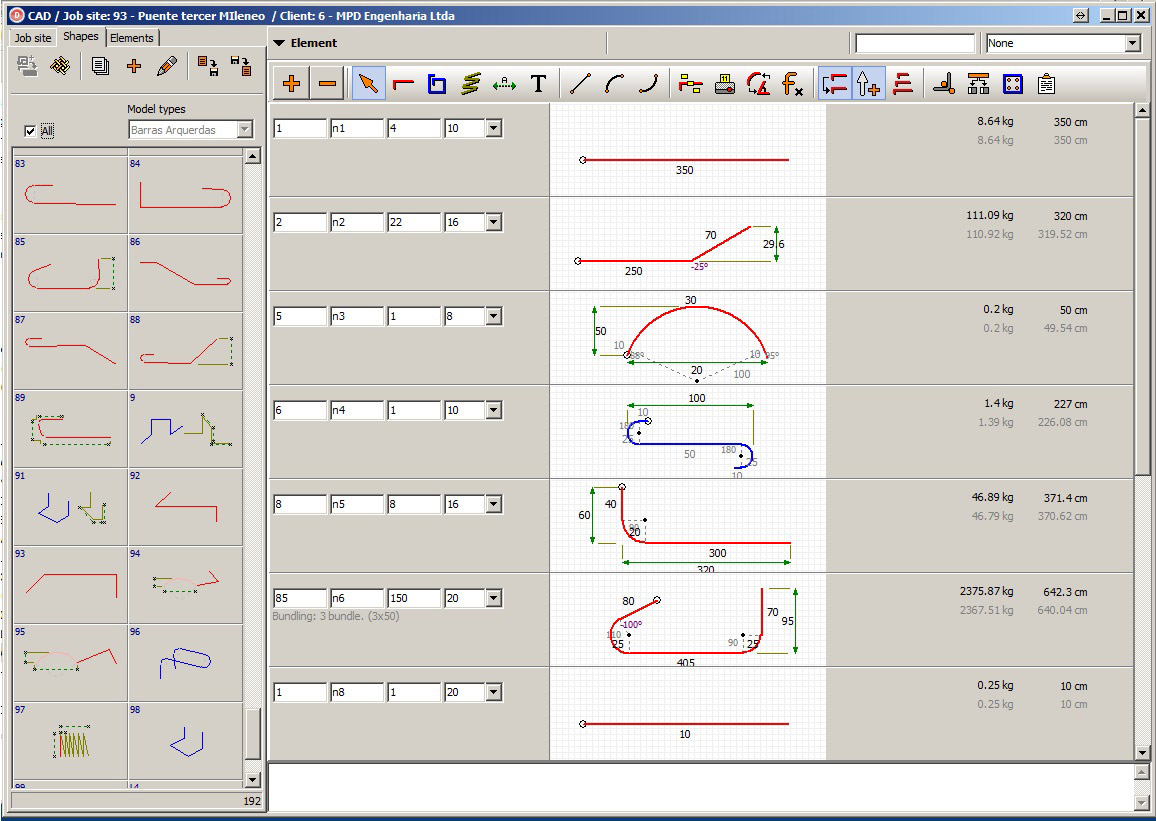

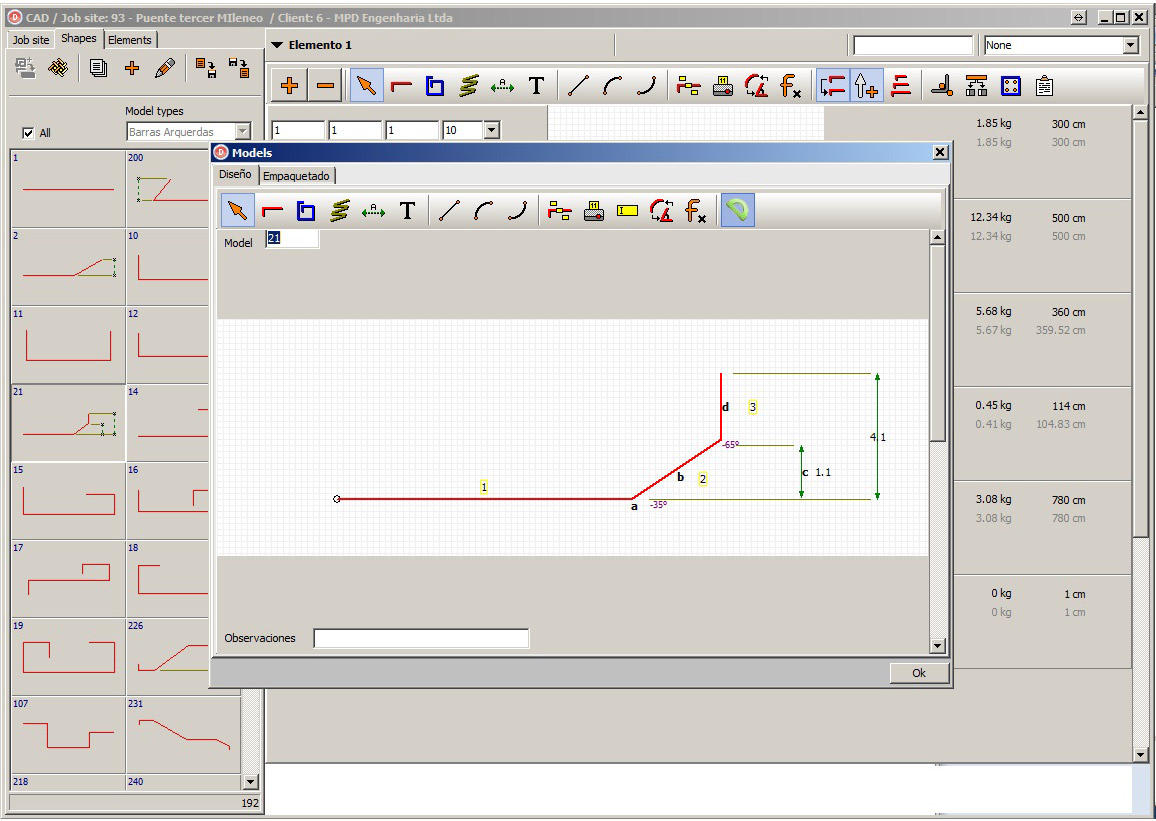

Thanks to the flexible Graphico Pro we can adapt to all the international metric systems. The user can use the program in centimeters, millimeters or Imperial even within the same project. It allows us to work on different configurations of diameters for each project, enabling us to store shapes and to automate the calculation, and also to create assembly drawings of our elements.

All the features of Graphico have been expanded and improved. Graphico Pro allows you to easily duplicate the data of the development, export or import projects or part of them, convert the data in standard files compatible with the recent market.

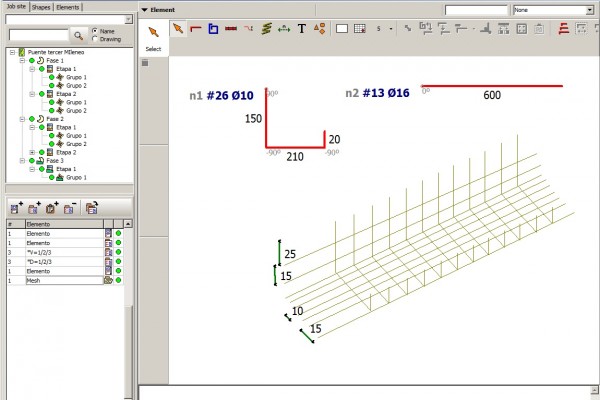

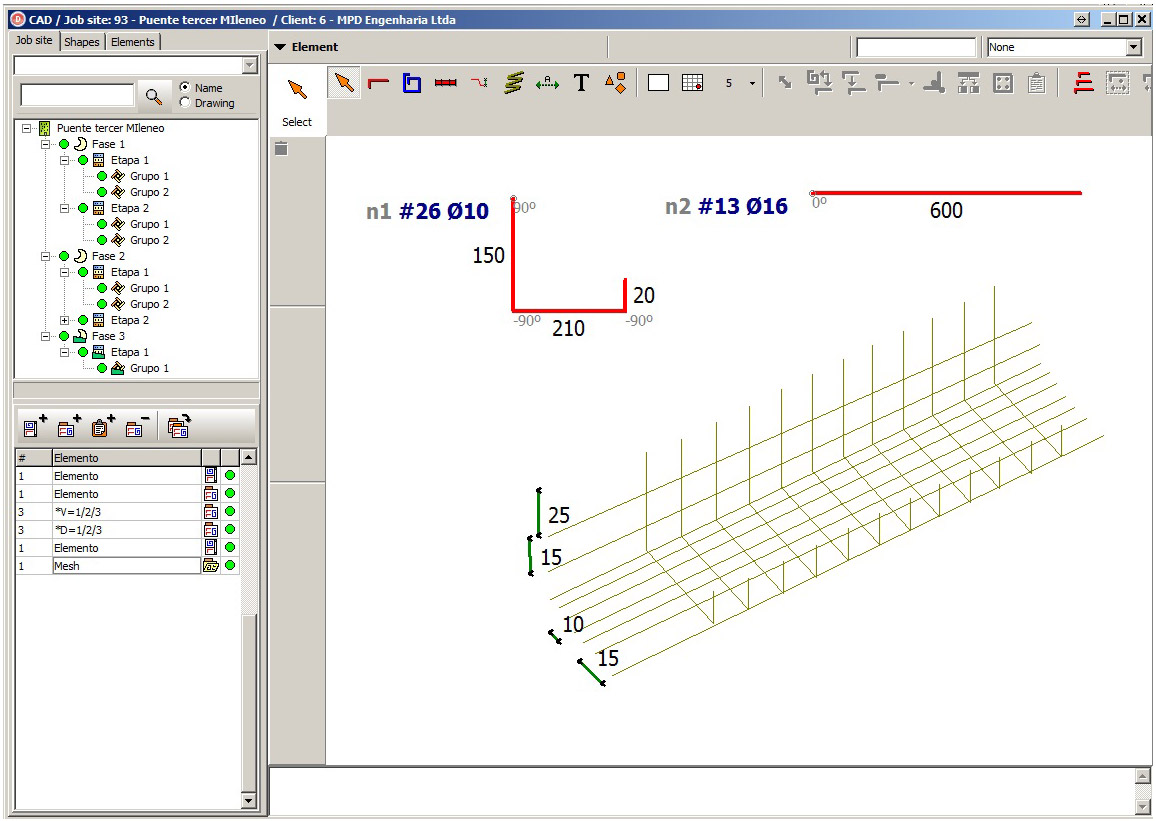

All in a single control system: Graphico pro also allows within the same project to follow the development for position, for element with the indication of the installation (CAD), to create meshes (Grafo-Mesh) and to include sales products.

The new architecture of the Graphico Pro data can withstand large volumes of information and manage multiple users connected to the same central system, meeting the needs of big companies that require centralized solutions and multiuser data sharing.

Features

Orders Management

Orders scheduling

Ability to connect with external CRM systems and on the Web to enable the customers to track their production orders .

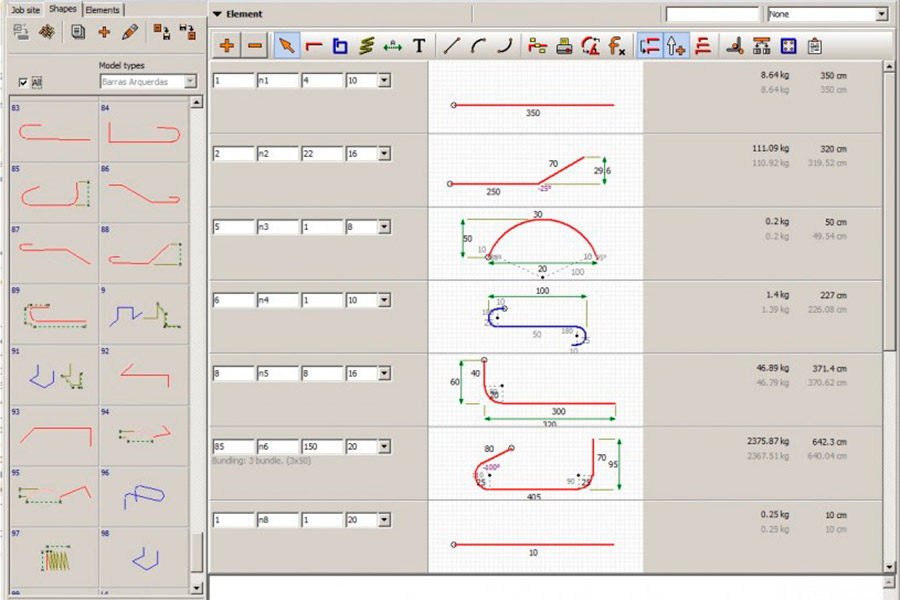

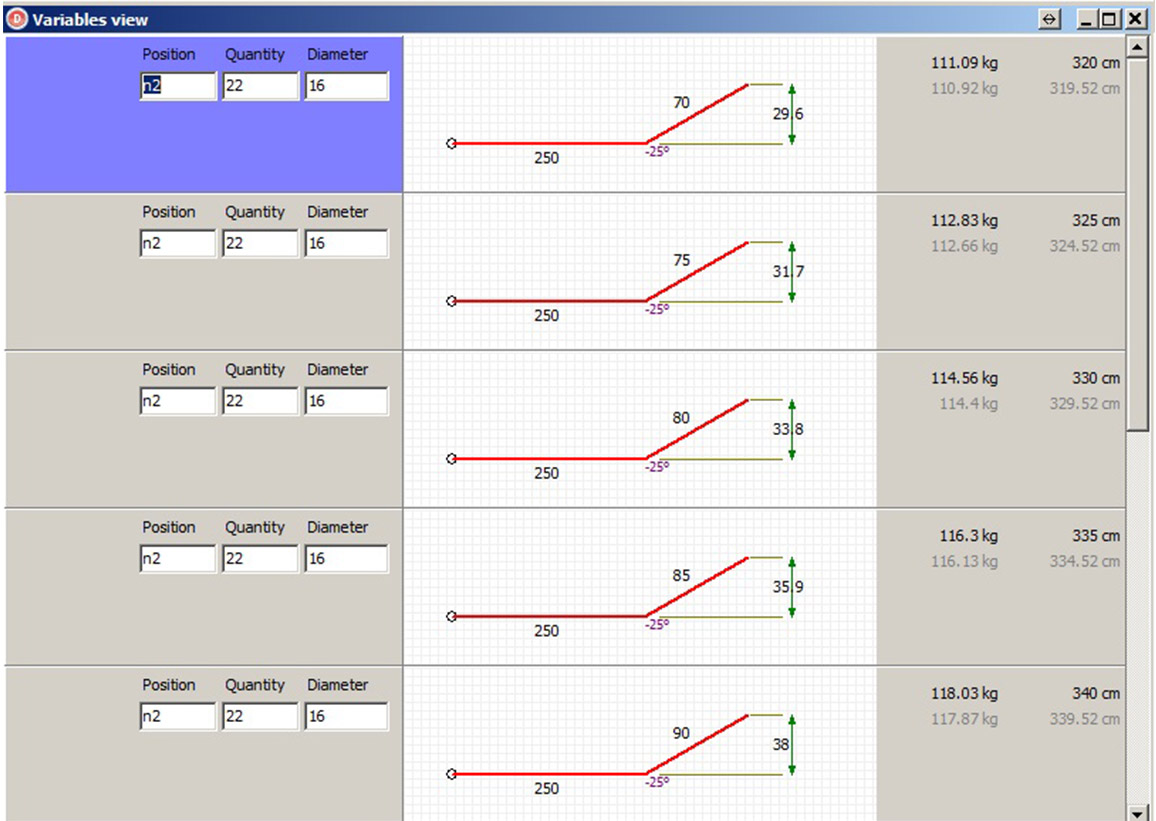

Orders Detailing

Graphico Pro is the only software that allows within the development to create loose positions, assembled elements and commercial products.

Assembled elements

Elements by position

Commercial products

Production orders

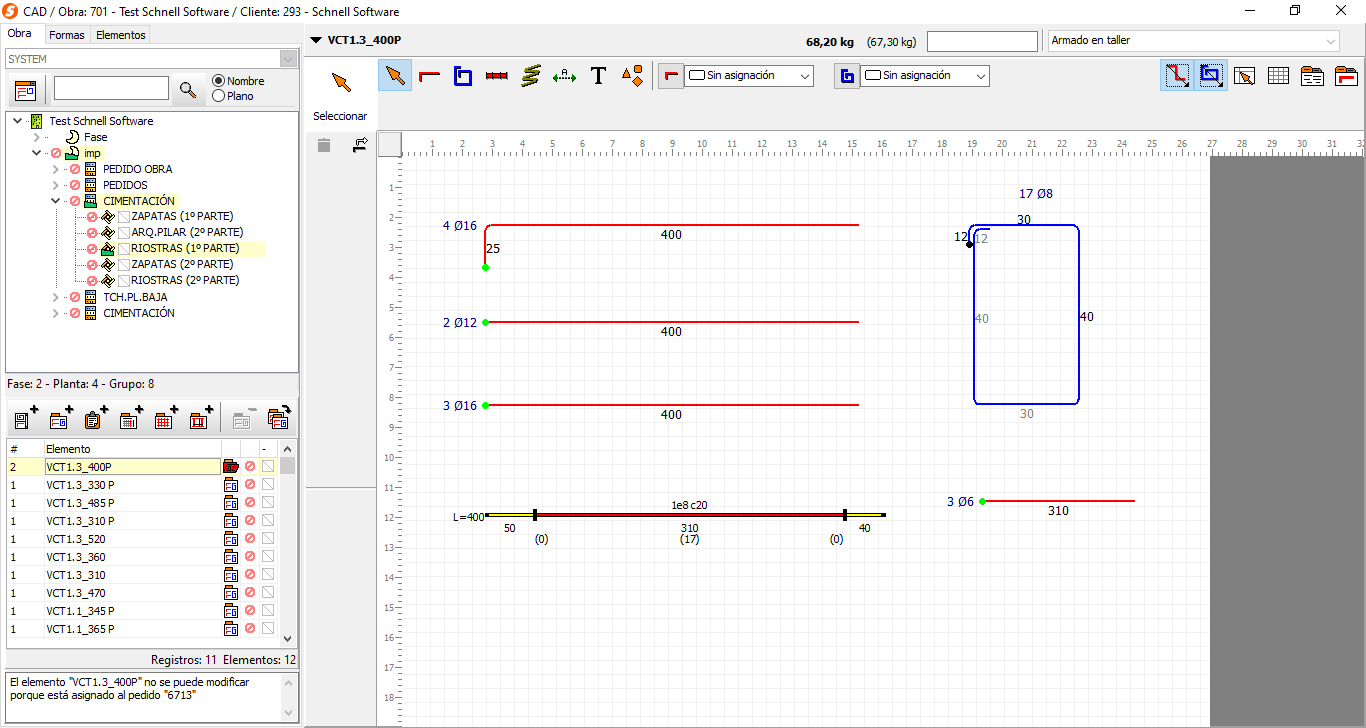

The schedule is made in the order where we can select the necessary levels (phase, floors, group, element, positions) to be included in the order. Graphico Pro allows you to assign complete elements, positions or commercial products in the same production order.

The system will give you the information about the schedule and the assigned to the production order. The system checks the positions assigned to an order and does not allow to assign them by mistake to others.

The production orders are a tool to check and plan the daily and weekly production. Several production orders can be assigned to a commercial order or to a customers order.

Production assignment

Once the production order has been created, the system allows you to assign the positions to the machines of the production plant. This tool allows you to distribute a production order of different machines, stirrup benders and cutting benches.

A filtering system helps the user to automatically assign the positions according to the geometry, the number, diameter, etc., to different machines.

The storage of standard scraps or reusable wires is seen in the system as a machine. Its menu is customizable as that of the machine.

Estimated production of an order:

Being all orders sent to the machines and thanks to DATA PRO MACHINE and PANNEL we have a feedback of all the production data; Graphico Pro manages and monitors the production/machine and estimates the production time of the order.

Production orders:

- Production order per day

- Grouping of orders per delivery