Rebar shop management

Grafo-Boss

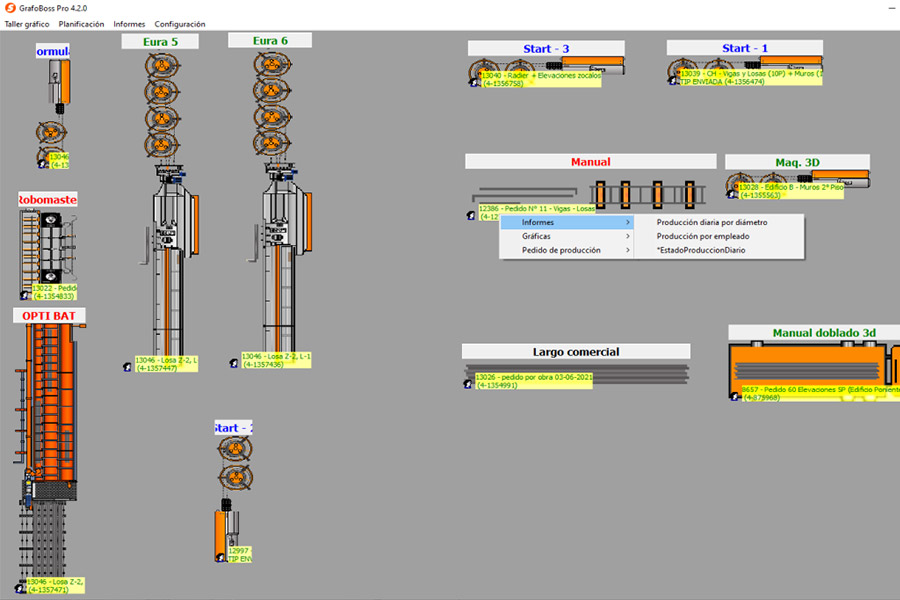

Grafo-Boss Program

El control de su planta en tiempo real

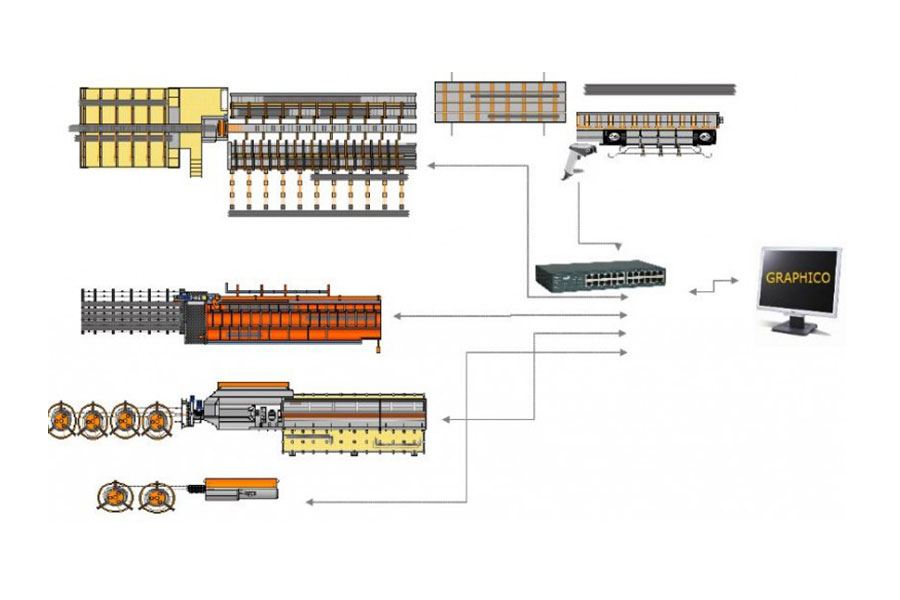

Grafo-Boss is an open system, based on a structure of computer network with Internet technology TCP-IP.

It can manage every production configuration in the rebar shop of cutting and bending. It’s compatible with any kind of production system: by element, by position, assembled elements, civil works

It’s embedded in the Graphico Pro System in a transparent way.

It can manage the operators, getting the weight worked by each of them.

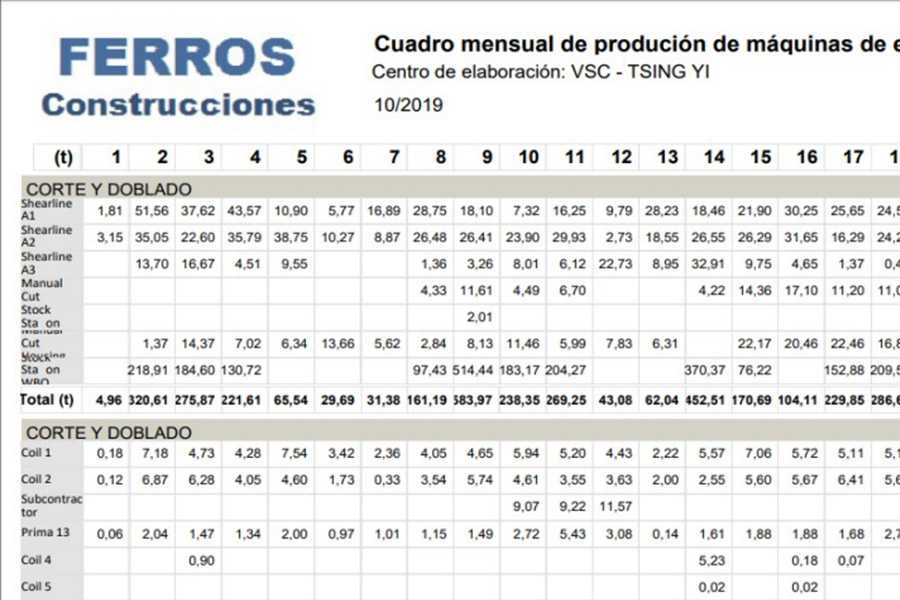

Production by sections and machines

Productivity reports

Operators path production

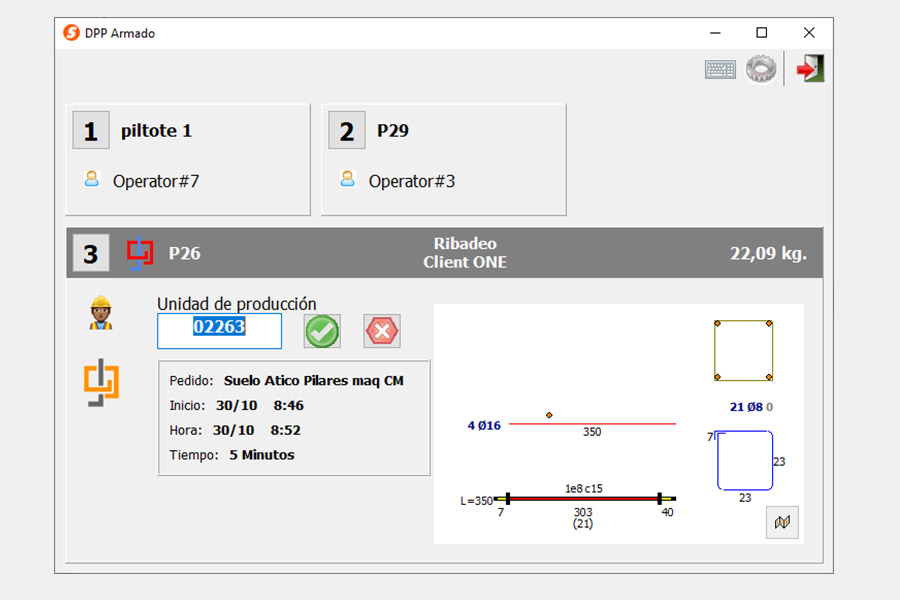

Data Pro Program

Get feedback from your rebar shop on-time

The system Data Pro permits to know in real-time the status of the orders in the factory, production timing of the orders in each machine and the management of the operators working in the system.

There are two options for connection: Data Pro Machine permits to connect through cable UTP and protocols TCP-IP the new Schnell machines with the central server.

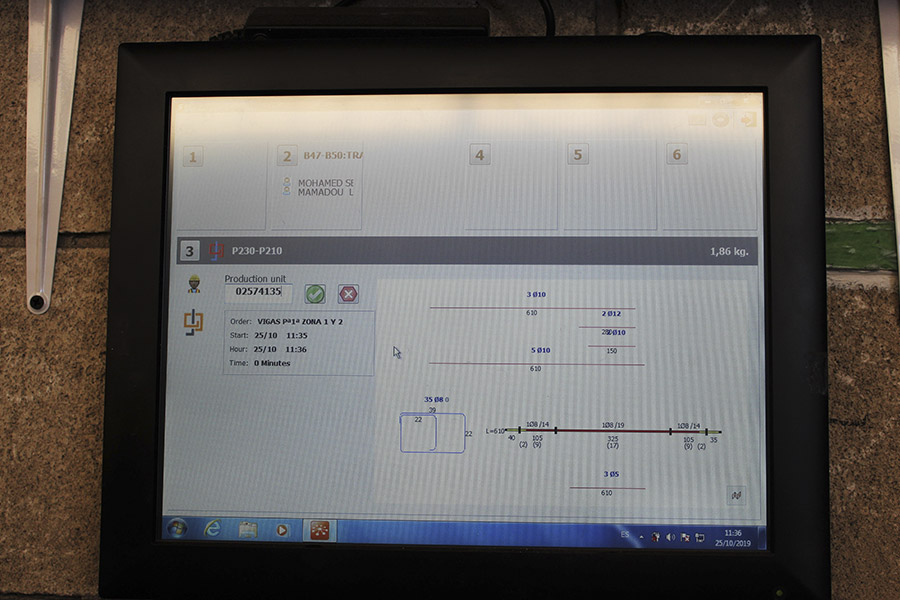

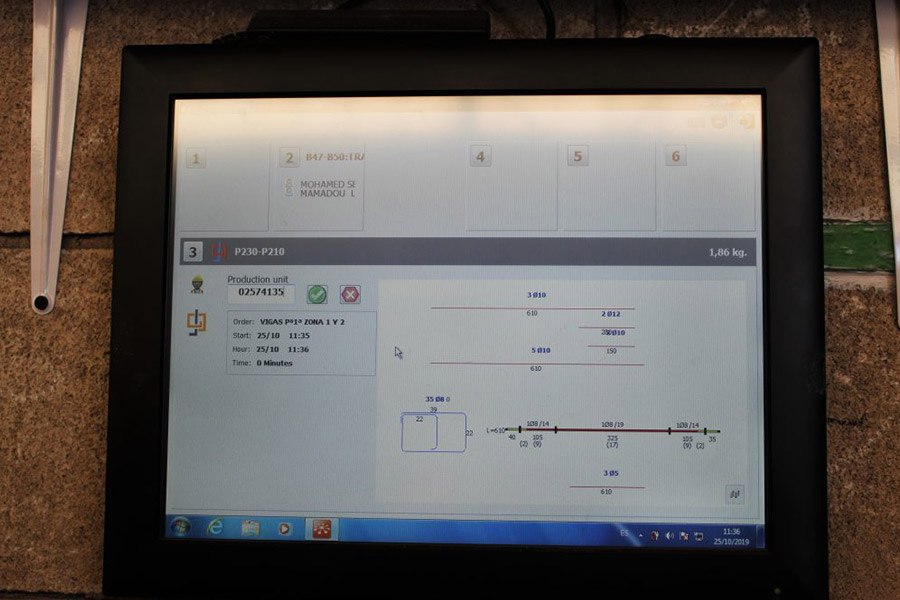

Data Pro Panel is connected to the central server through touch screen computers, that permit the tracking of the production from any machine or manual production workstation.

Data Pro Panel

Data Pro Machine

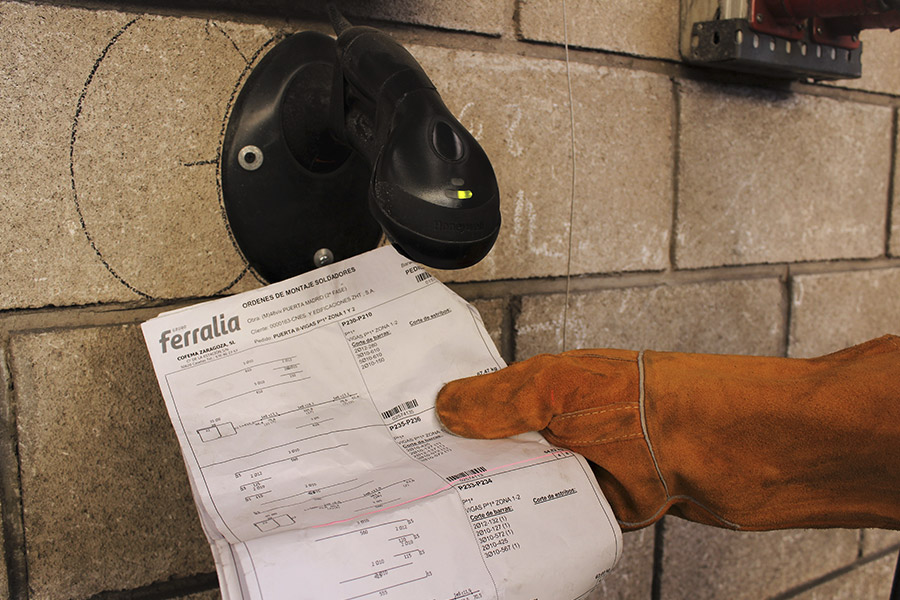

Using the Grafo-Trax module together with the Data Pro System it’s easier to register the raw material tracking.

The system record automatically the heats of the material used in each workstation and assign the production tags of each order automatically. Material tracking and stock management is automatic.

Install the material tracking with the Data Pro and get its advantages